Industrial Challenges

Construction sites, batching plants, and industrial operations face critical energy management challenges that directly impact profitability

Uncontrolled Fuel Costs

- • DG sets run idle for hours

- • Fuel wastage adds lakhs of rupees monthly

- • No way to calculate cost per unit of electricity produced

Equipment Breakdowns

- • Voltage fluctuations damage expensive machinery

- • DG trips cause hours of project delays

- • Heavy equipment highly vulnerable to poor power quality

Inefficient Operations

- • Machines run together without efficiency analysis

- • High diesel usage per cubic meter of output

- • Poor scheduling of batching cycles, compressors, pumps

Lack of Visibility Across Sites

- • Managers cannot be physically present on multiple projects

- • Manual log checks are slow, error-prone, and unreliable

- • Compliance and reporting take too much effort

The Solutions We Provide

Transform your industrial operations with comprehensive energy monitoring and optimization

Control Operational Costs

- • Real-time tracking of kWh and DG loads

- • Detect and eliminate idle runtime

- • Enables cost-per-unit calculation for electricity produced by DG

Ensure Equipment Health & Safety

- • Continuous monitoring of voltage, frequency, harmonics

- • Alerts prevent overloads and power stress

- • Protects machinery from damage and avoids downtime

Improve Energy Efficiency

- • Detailed reporting by phase and load

- • Optimize scheduling of heavy machines

- • Benchmark diesel-to-output (fuel efficiency)

Remote Monitoring & Compliance

- • Remote access through Modbus and dashboards

- • Multi-site, real-time visibility in one dashboard

- • Audit-ready reports for compliance and green norms

Solution Stack

Complete hardware + software stack that transforms raw electrical signals into actionable insights for cost savings, reliability, and compliance.

Hardware

Elmeasure LG6400P Energy Meter

Measures voltage, current, power factor, frequency, and energy (kWh). Supports RS485 Modbus RTU communication for industrial reliability.

Teltonika FMB/C 125 IoT Gateway

Acts as a transparent RS485 bridge, enabling real-time data acquisition and transmission.

CT (Current Transformer) Coils

Non-invasive current sensing for each phase (R/Y/B), ensuring accurate and safe current measurements.

How It Works

Measure

Three CTs feed phase currents to the LG6400P; the meter also measures per phase voltages and computes power, PF, frequency, and kWh.

Connect

The LG6400P's RS485 (+/–) connects to the FMB/C 125's RS485 A/B lines for seamless Modbus data communication and transmission.

Visualize & Act

The Aether Dashboard converts raw data into actionable insights. Track KPIs, detect anomalies, generate reports, and make informed decisions.

Software

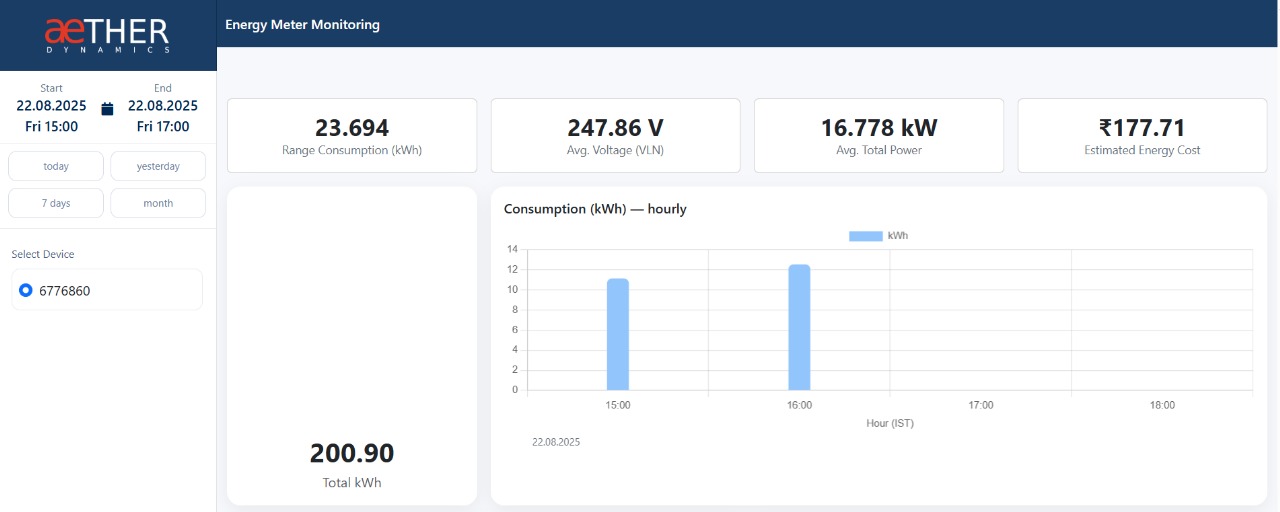

Aether Portal – KPIs

The dashboard turns raw data into insights. Our Energy Dashboard gives you clear KPIs and derived metrics for comprehensive energy management.

| KPI | What you see | Why it matters |

|---|---|---|

| Range Consumption (kWh) | Energy used over a selected period (Day/Week/Month/Custom) | Validates savings after changes; spots unusual spikes |

| Total kWh | Cumulative energy consumed since meter commissioning or last reset | Audit-ready totals for reconciliation and billing |

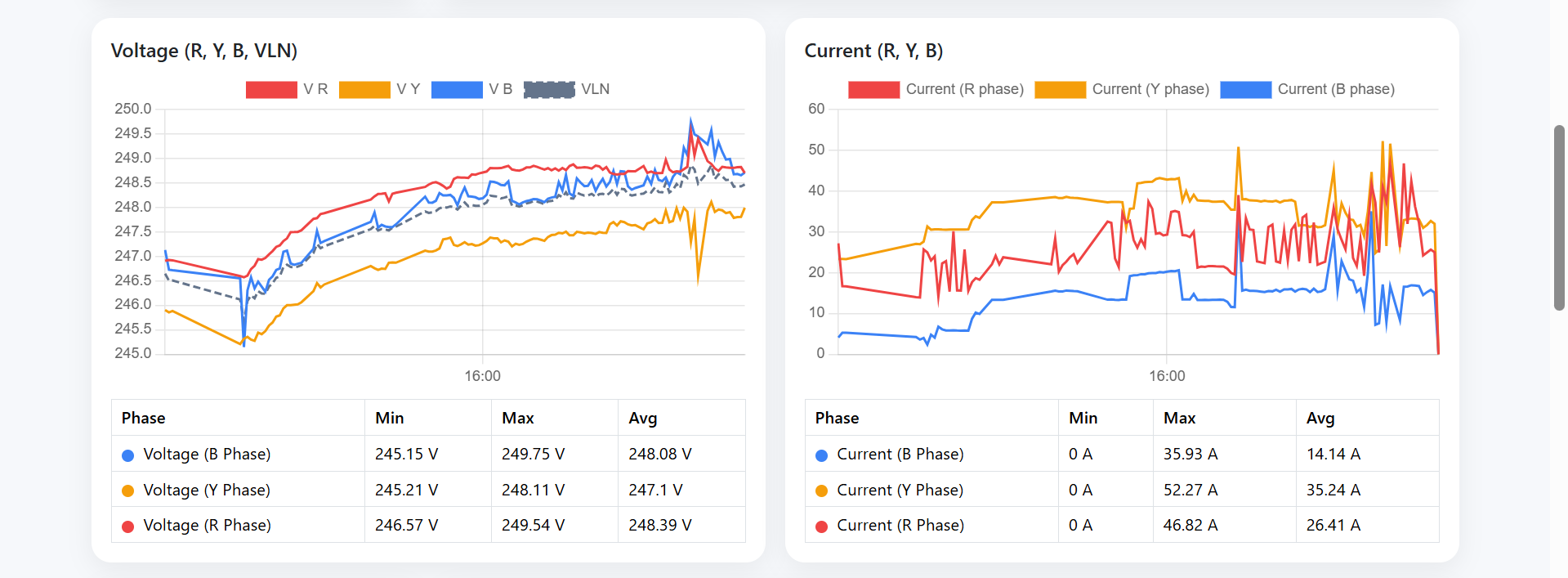

| Voltage (R, Y, B, VLN) | Per‑phase voltage and phase‑to‑neutral (VLN). Balance indicators | "Is the supply clean & balanced?" Prevents equipment stress |

| Current (R, Y, B) | Per‑phase current draw; phase balance tiles | "Are loads shared fairly?" Avoids overheated cables and nuisance trips |

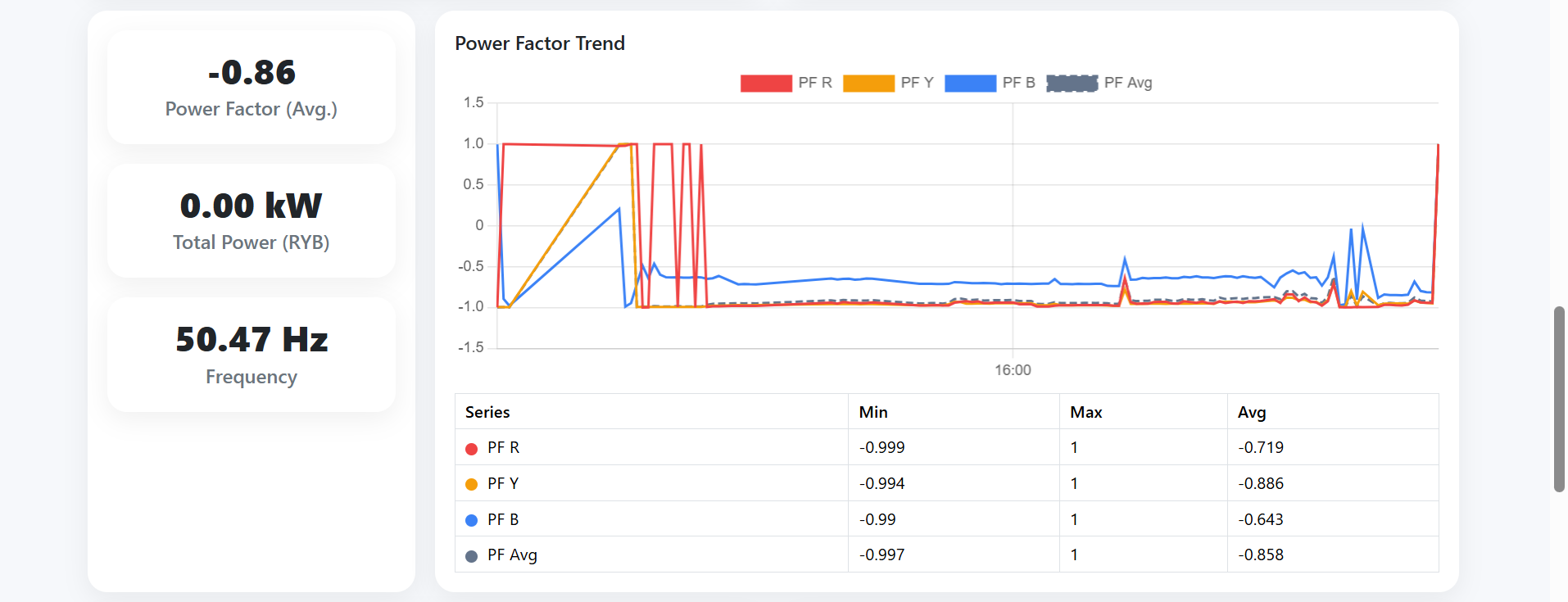

| Power Factor (PF) Trend | PF over time with target band | "Are we using current efficiently?" Reduces penalties and losses |

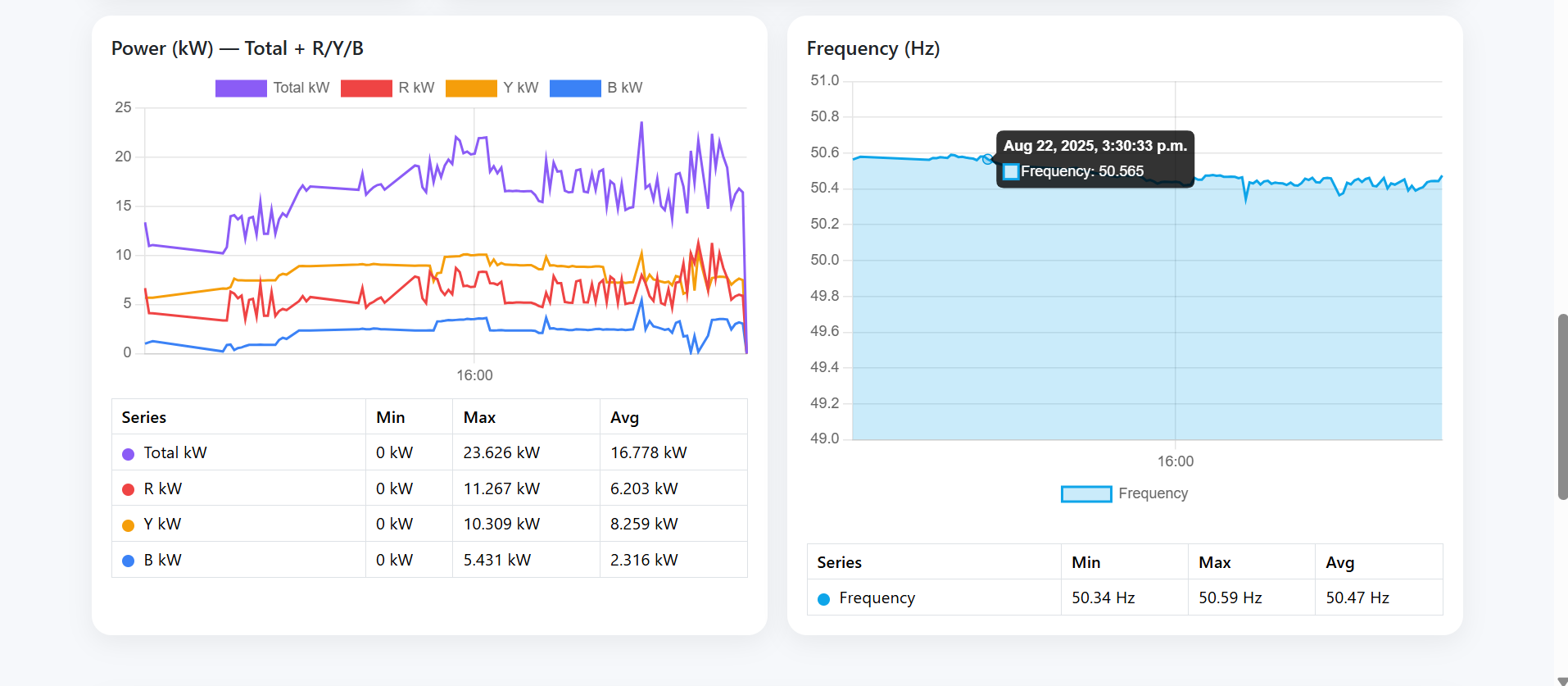

| Power (kW) — Total + R/Y/B | Real power by phase and total, compared to your configured load band | "Is the DG loaded right?" Cuts fuel waste from under‑loading |

| Frequency (Hz) | Generator frequency with stability band | "Is the governor steady?" Early warning for mechanical issues |

Aether Energy Dashboard

Energy Monitoring Dashboard

Real-time energy consumption monitoring with live kWh tracking, voltage/current readings, and power factor analysis. Get instant alerts for abnormal consumption patterns and optimize your DG set performance for maximum efficiency.

Load Trend Analysis

Track load patterns over time with detailed trend analysis. Identify peak usage hours, optimize machine scheduling, and reduce idle runtime. Historical data helps predict future consumption and plan maintenance schedules.

Power Factor Monitoring

Monitor power factor in real-time across all three phases. Detect poor power factor that leads to penalties and equipment stress. Optimize reactive power consumption and improve overall electrical efficiency.

Power (KW) and Frequency Monitoring

Track real-time power consumption in kilowatts and monitor generator frequency stability. Ensure optimal DG loading, prevent under-loading waste, and maintain consistent power quality for sensitive equipment.

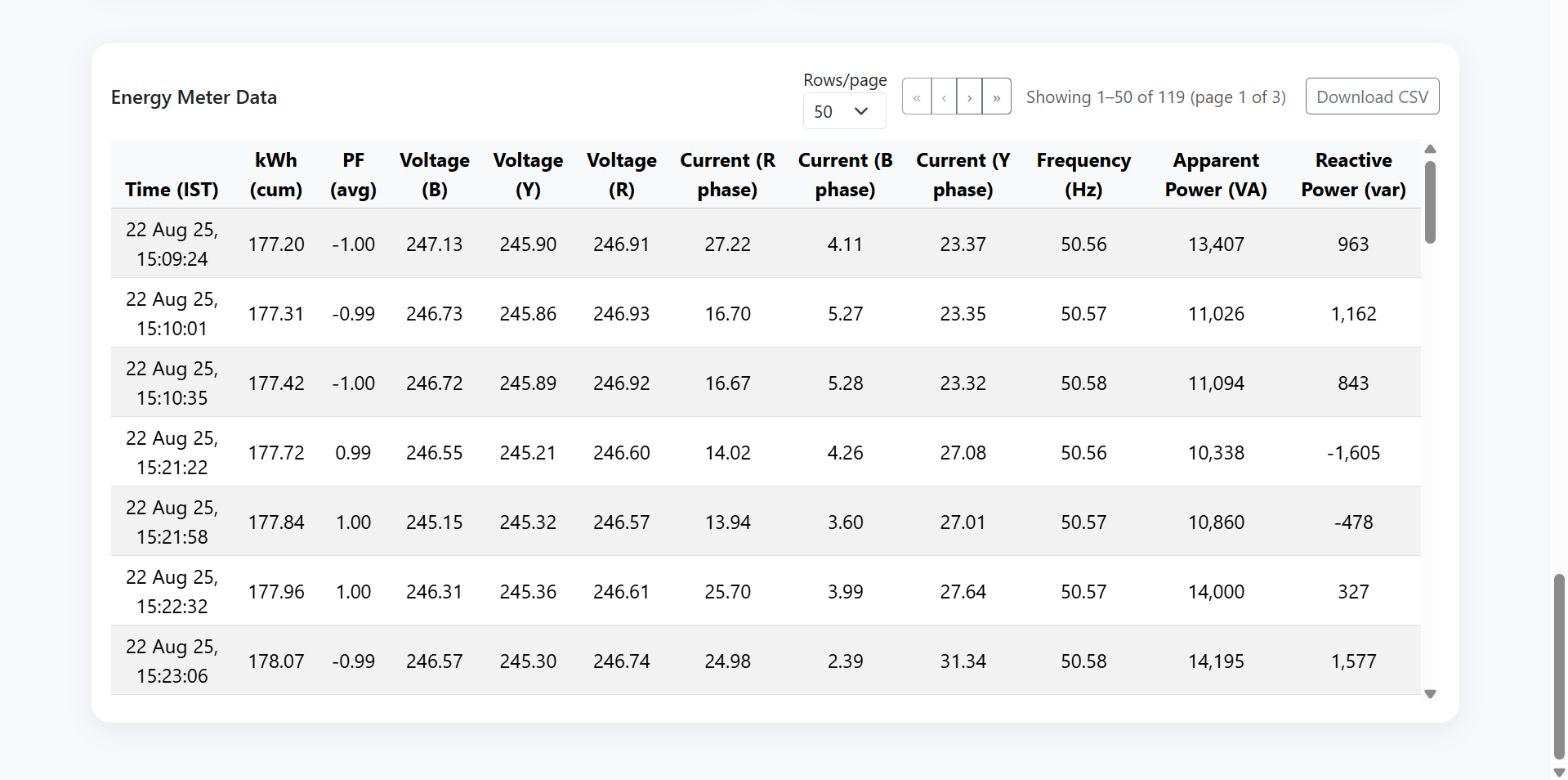

Energy Meter Data Report

Generate comprehensive energy consumption reports for billing, compliance, and optimization analysis. Export data in multiple formats, track cost per unit, and maintain audit trails for regulatory requirements.

Key Features of Energy Monitoring System

Comprehensive monitoring capabilities for industrial power management

Real-Time Energy Monitoring

Monitor kWh consumption, voltage, current, and power factor in real-time across all three phases for complete visibility.

Power Quality Analysis

Detect voltage fluctuations, frequency variations, and harmonics to protect expensive machinery from damage.

Remote Access Dashboard

Access energy data from anywhere through web application with multi-site visibility in one dashboard.

Alerts

Get instant notifications for overloads, power outages, equipment failures, and efficiency anomalies.

Comprehensive Reports

Generate detailed energy consumption reports, efficiency analysis, and compliance documentation.

Load Optimization

Optimize DG set loading, balance phase loads, and schedule heavy machinery for maximum efficiency.

Hardware Components of Energy Monitoring System

Elmeasure LG6400P 3-Phase Energy Meter

Elmeasure LG6400P 3-Phase Energy Meter

Industrial-grade energy meter providing comprehensive electrical measurements with high accuracy and reliability for critical applications.

- 3-Phase voltage & current measurement

- Real & reactive power calculation

- Power factor monitoring

- Frequency measurement

- RS485 Modbus RTU communication

- Class 1 accuracy (±1%)

- Wide operating temperature range

- DIN rail mounting

Teltonika FMB/C 125 IoT Gateway

Teltonika FMB/C 125 IoT Gateway

Advanced IoT device that acts as a transparent RS485 bridge, enabling seamless data transmission from energy meters to cloud platforms.

- 4G LTE connectivity

- RS485/RS232 interfaces

- Internal GPS tracking

- Battery backup

- Multiple I/O ports

- Industrial IP67 rating

- Remote configuration

- Data buffering capability

Current Transformer (CT) Coils

Current Transformer (CT) Coils

High-precision current transformers for non-invasive current measurement on each phase, ensuring safety and accuracy in industrial environments.

- Non-invasive installation

- High accuracy (Class 1)

- Wide measurement range

- Split-core design

- Temperature compensated

- 5A secondary output

- Robust construction

- Easy cable retrofitting